PCB Manufacturing Services

- Standard, Advanced, HDI, Multilayer PCBs, Flexible, Rigid-Flex boards, Aluminium PCBs, prototypes to small batches.

- Rigorous testing, and we are fully compliant with IPC standards.

- Instant online quote and ordering system, which is easy, convenient, and time-saving.

- We have professional standard reviewers that ensure strict quality control measures in every production process.

- We leverage advanced testing technologies, such as AOI Test, E-Test, X-RAY, and Impedance Control.

- We have an in-house PCB design and assembly process review, which ensures high-quality products. We're committed to helping you get the highest quality at competitive prices with our industry experience.

- We use a wide range of PCB material options, such as FR4, High TG FR4, Rogers PCB, Metal-based PCB, and High-frequency Materials.

- We have a superior customer care department, which supports person-to-person services. Our customer care department is flexible and approachable if you want to make any updates before the production process begins.

PCB Manufacturing

Capabilities

WellPCB is a reputable and professional PCB manufacturing and assembling company with roots in China.

The table below shows some of the primary capacities that we provide and support.

It contains information about the PCB materials we use, the PCB technologies we leverage, the types of products we manufacture, and our offer’s tolerances.

-

Materials:FR4, High TG FR4, Halogen Free Material, CEM-3, Rogers HF Material

-

Min.Contour Tolerance:+ / -0.1mm

-

Layer Counts:2-36 Layers

-

Min.Finished Diameter of PTH Hole:+ / -0.1mm

-

Finished Copper Thickness::0.5-5 OZ

-

Max.Board Thickness/Hole Ratio:12:1

-

Finished Board Thickness:0.2-6.0mm

-

Min.Solder Mask Bridge:4mil (Min,SMT Pad Space 8mil)

-

Min.Line/Track Width:3mil

-

Min.Legend(Silkscreen) Track Width:5mil

-

MIN.Drilling Slot Size:0.6mm

-

Surface Treatment:Leaded HASL, Lead Free HASL, Immersion Gold, OSP, Immersion tin, Immersion Silver, etc.

-

Solder Mask Color:Green, Black, Blue, White, Yellow, and Matt, etc.

-

Other Technology:Gold Finger,Peelable Mask, Non-across Blindried Vias, Characteristic Impedance Control, Riged-flex Board etc.

-

Solder Mask Hardness:6H

-

Legend/Silkscreen Color:Black, White, Yellow, and others.

-

Wrap and Twist:≤0.7%

-

Flammability:94v-0

The PCB Manufacturing

Process

We use the data (Gerber file) that you send us to create the production information for your customized boards. Our experts match your specifications with the capacities for compliance purposes.

When we make the circuit board, the imaging process is what defines the circuit traces. The traditional imaging process needs a UV-light and photo-tool to transfer images, while LDI only uses a computer-controlled, highly focused, laser beam to directly define the circuit pattern onto the board.

Here, we leverage the etching process to eliminate any undesirable copper residues from the panel. After removing it, we also remove the dry film to remain with copper circuitry, which is in line with the PCB design. So basically, etching is the removal of undesired chemical and electronic residues.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

We apply an oxide layer to the inner board layers and then stack them together using prepreg to create insulation between them. Additionally, we should add copper foil to the upper and lower stack parts.

In this step, we bore the holes that will later act as electrical contacts in the multilayer board. Drilling is a mechanical process that PCB manufacturers optimize to obtain registration to the internal layer links. It is important to note that we can still do laser drilling. We have a laser drilling machine, which can drill 3-6mil vias.

First, we apply some thin copper layer deposits on the holes we drilled earlier on the walls. PTH offers the best copper deposits, which conceal the hole walls and the whole panel. And this is a chemical process that we should strictly regulate to plate sufficient copper deposits into the non-metallic walls. Secondly, carry out panel plating to get a thicker outer copper deposit.

Outer layer imaging resembles the internal layering process. However, in outer layer drilling, we get rid of the dry film and maintain the circuitry. Then plate the extra copper later in a clean environment.

This is the second electrolytic plating process, where we carry out extra plating in dry film parts (circuitry). After depositing the copper, we should apply tin to prevent the plated copper from oxidation.

First, we take out the dry blue film. Secondly, we scrape all the unwanted copper residues. The tin deposits resist the etching process, therefore, protecting the copper deposit we want. Lastly, we chemically eliminated the tin residues to leave behind the circuitry.

With the help of artwork and Ultraviolet light, expose some PCB parts and remove all the exposed parts. Then completely cure the remaining solder mask to create a quality finish.

Surface finish can maintain the exposed copper circuitry meanwhile provide a solderable surface when soldering components to the PCB. Usually, metallic and organic are the two main kinds of surface finishes. Metallic surface finish includes HASL, ENIG/ENEPIG, Immersion Silver, Immersion Tin, while organic surface finish includes OSP and Carbon Printing.

We will test all the boards before shipping to ensure all of the printed circuit boards are free of defects and meet the standards you expect. Currently, we have two different types of testing equipment available to test the circuit boards. Some test machines include flying probe, fixtureless testers. And we also have universal grid testing capability. These machines use fixtures built specifically for your PCB. If you have impedance control requirements, we will also test the impedance value of the coupon.

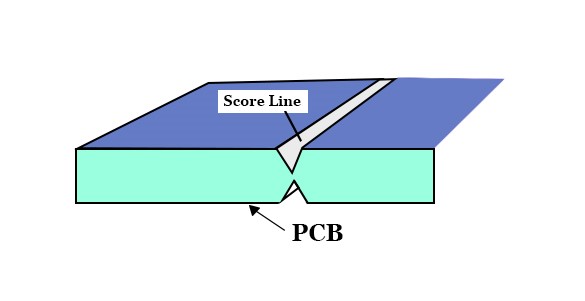

Here, we route the PCB production panels into particular sizes and shapes according to the production file. PCB V-Scoring is a process of cutting a ‘V’ shaped groove at the top and bottom of a printed circuit board, leaving a thin layer between the Vees. Once we have done this, it can easily separate the PCB Board at the V by applying minimal pressure.

In this step, a team of sharp-eyed individuals scrutinizes each product. The process involves visually examining the board in line with the set standards.

- Prototype orders placed within 24 hours

- Normal lead time (5-7 Working days for some PCBs prototypes and small batch production)

- Faster lead time (48 hours for some PCBs prototypes and small batch production)

why us

Since 2007, WellPCB has offered good-quality PCBs with excellent turnaround times and customer satisfaction. We are one of the biggest and most skilled board manufacturers in China. Our committed staff- with a rich experience in the electronic world- produce superior products, such as double-sided, single-sided, multilayer, and HDI PCBs.

PCB & PCBA One-Stop Service

- We offer in-house PCB manufacturing.

- We procure original and authentic PCB materials.

- We procure components from authorized suppliers.

- We offer stencil and assembly services.

Unbeatable Prices on PCB Products

- We offer one of the most competitive prices in the PCB manufacturing world.

- We have our factories with genuine cost control and no hidden charges.

- We support numerous payment methods, such as T/T, credit card, PayPal, bank transfers, etc.

- Our factories offer price support for different orders, especially for multilayer boards and mass production.

On-Time Delivery

- Our main delivery channels are DHL, FedEx, and door-to-door services. Typically, shipping takes 2-4 days.

- We have developed a good relationship with the major shipping companies, and they offer discounts to us.

- We provide Anti-static + Moisture-Proof + Anti-Vibration Packaging and Inspection Certificates.

Quality Assurance

- Our products adhere to the IPC and the ROHS and REACH Standards.

- We boast of over 99% customer satisfaction rates.

- We have standardized factory processes and management.

- We pass our products through multiple testing procedures.

Excellent Customer Service

- We offer instant online quoting and ordering services.

- We guarantee quality in our services.

- We have unbeatable prices and offers, and we do not require a minimum order quantity.s.

- We have a 24/7 and experienced support team available via online, phone, and email.

Rigorous Quality Control System

- We operate strictly in line with international quality standards, guaranteeing 100% shipment quality.

- Our thorough inspection procedures warrant high PCB dependability and stability.

Return and Refund Services

- In case of any severe default in our products, you can request compensation or a refund.

- We refund directly to your preferred payment method. We can also rework or refabricate the product and reship it at our expense.

Professional Technical Team

- We are a one-stop PCB manufacturing and service provider offering customized, fast, and high-end products.

- We pride ourselves on decades of PCB production, offering optimized printed circuit boards worldwide.

- We have hired the top-cream personnel with rich experience in standard PCB fabrication and advanced PCB fabrication.

PCB Factory Scale

We handle all production scales, including small, medium, and mass production orders.

Besides, we can deliver more than 10,000 products monthly.

We have competitive prices and unbeatable offers for volumes ranging from as small as 1 square meter for you.

Our Certifications

Here are the certificates we have:

IATF 16949:2016 ISO 9001:2015 ISO14001:2015 ISO13485:2016 UL Also, all our products follow the IPC & ROHS Standards. More importantly, we always strive to manufacture high-end PCB products.

PCB Product Show

Testimonial

NXP France

Top Questions

1.What PCB service do you offer?

We offer three primary PCB assembly services: PCB fabrication, consigned PCB assembly, and full turnkey services,As a PCB manufacturer, we offer One-Stop Solution during the electronic manufacturing services. We comply with PCB fabrication process industry standard.

2. Is it possible to get stack-up drawings from you?

Yes, we are willing and ready to share some of our standard stack-up drawings with you, or even individual stack-up drawings that meet your specific requirements.

3. Do you offer any discounts?

Our two factories offer price support for various orders, especially for multi – layer PCBs and mass production. You can get Custom Circuit Boards with cheap price.

4. Can you view and process Altium CAD data directly?

Unfortunately no. We generally deal with Gerber files. Other design files are not available now.

5. What if I am dissatisfied with PCBs from WELLPCB.com?

If you encounter any problem with our products or feel dissatisfied with our products or services, you can let us know through [email protected]. We promise to get back to you within 24 hours and serve you satisfactorily. We will either refabricate your PCB in case of a defect or refund the full amount without needing to return the defective PCBs. You may also choose to credit your[email protected] account and use the credit for future orders.

6. Do you offer circuit board design/electronics design?

No. We do not design for manufacturing. You could send us your circuit design files.

7. What to consider during PCB fabrication process?

First, you need to take the board materials into consideration, like the flexible substrates, common insulating substrate. Then, the PCB layout /board layout, board components, board edge. Also, for finish surface, Immersion Gold Circuit Board or OSP, etc. Besides, the surface-mount packaging, like ball grid array(BGA), or QFN, etc. For more considerations in the PCB manufacturing in PCB industry , please contact our team.

8. What is the layer of copper?

As for the layer of copper, for Rigid boards, the copper layer is 1-32L. For Rigid-flex Board layers, 11-20L. For more questions about PCB Copper thickness( finished copper weight), copper traces, or the excess copper, unwanted copper, please contact our technical team and we are more than happy to serve you.

9. Why is PCB in green color ?

That’s the solder mask color, which protects the copper circuits printed on the glass fiber core to prevent short circuits, soldering errors, etc. The green mask makes the board surface its appearance.

10. Should I choose plated-through holes or Castellated Hole?

For hole plating, that depends on your need. We will manufacture as per your original design.